CUSTOM MAGNETICS & ASSEMBLIES

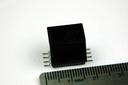

Custom products are the special focus of BH Electronics. For each application, be it small or large, our engineers draw on extensive resources and experience to create exactly the right product for each application. Once designed each product is constructed as a prototype to verify the design and provide our customer with an example of the finished item for testing in their facility. These prototypes are prepared in our complete prototype facilities which include special machining, molding and assembly processes as well as extensive testing equipment. Examples of typical product developed in this way are shown below.

Engineering Expertise

BH Electronics’ strength in engineering design are coupled with deep manufacturing expertise that provides unique capabilities for product development and re-engineering. Our team of experienced design engineers specialize in collaborating with our customers to develop exceptional products that meet or exceed their requirements and needs.

Our list of services include:

- New Product Design: All aspects of the product development process from concept development through manufacturing and testing to meet our customer’s specifications and requirements

- Re-engineering: Improving existing designs for performance

- Reverse Engineering: Utilizing extensive history and knowledge based to recreate legacy components no longer supported by their original equipment manufacturer (OEM)

- Prototype Manufacturing: A fully equipped engineering lab capable of assembly and testing

- Program Management: Planning and management of engineering design, prototyping, production, testing, as well as implementation of factory resources and raw material to ensure products are high quality and delivered on time

QUALITY ASSURANCE

Our commitment to quality is proven with our ISO 9001 Quality System, and our decades of experience as a cost effective, high quality magnetics engineering and manufacturing company. From initial customer consultation to design review to high volume manufacture, we follow a rigorous quality process that includes:

- Prototype construction and product approval.

- Process development and approval in the U.S.

- Process approval at the manufacturing location.

Our test equipment is calibrated to NIST standards to ensure consistent results.